by mechanic403

Introducing the worlds first Semi-automatic Revolver Crossbow!

Its small, compact and can fire 3 shots in a row just by pulling the trigger; no cocking or reloading required between shots. Simply pre load all three barrels and rotate them into the firing position, then let loose!

Relatively short print time (around 7 hours total) and only requires a few standard M3 and M2 screws and some rubber bands.

Includes file for a fully printable mini-arrow

Since Thingiverse's Markdown is broken, Ill list all assembly instructions here

Youll need the following materials:

PVC pipe with 1in Outer Diameter and 3/4in Inner Diameter (27mm Outer Diameter, 21mm Inner Diameter) cut to 130mm length

7 M3x8

7 M3x16 and Hex nuts

6 M3x20

1 M3x10 and Hex nuts

3 M2x20

6 Strong rubber bands

1 very small rubber band

Super glue

Youll want to print several copies of certain parts. The multiplicities are listed here. If the part isnt listed here, just print one.

ArrowGuideBottom x 3

ArrowGuideTop x 3

RevolverGuideFrame x 2

ArrowSled x 3

StringReleaseHook x 3

StringPulley_Inner x 6

MiniArrow x 3 (or more!)

See the Print Settings section below for layer height, supports and infill settings

For the Handle, youll want to print Handle_Left, Handle_Right and MainTrigger. Youll also need an M3x10 screw, an M3x16 screw and two M3 Hex nuts.

Connect the two handle halves with the M3x10 screw going through the lower hole and secure with a hex nut. Next, place the MainTrigger into the small slot between the two halves and insert the M3x16 screw through both halves and the trigger such that the trigger can freely rotate around the screw axis.

Finally, double wrap the very small rubber band around the top portion of the trigger and loop around the small hook on the top of the Handle.(See fig 1 below). It should be able to return the trigger back to its extended position with a decent amount of resistance.

You can apply some glue to the inside surfaces of the handle halves if you want them to be extra secure, however I have found this to be unnecessary.

First, youll want to print 3 copies of the Arrow Guide Sub-Assembly, which is the collection of parts that handles shooting the projectile. This sub-assembly consists of the following parts:

ArrowGuideTop

ArrowGuideBottom

ArrowSled

StringReleaseHook

StringPulley_Inner x 2

Strong rubber bands x 2

M3x8 screws x 2

M3x16 screws x 2

M3x20 screws x2

M2x20 screw

Once all of the parts have been printed and materials gathered, assembly continues as follows:

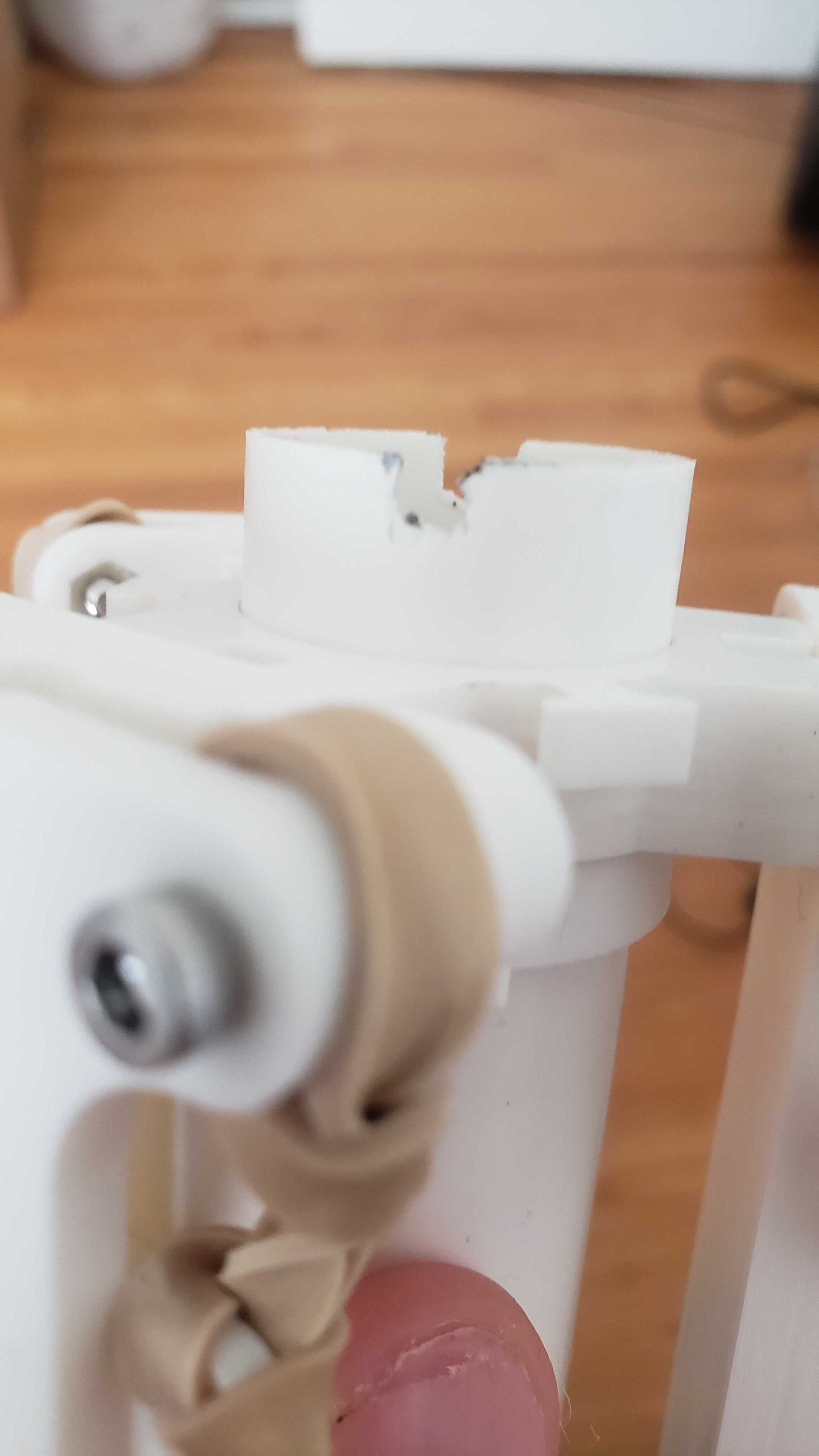

Insert the StringReleaseHook into the slot at the rear of the ArrowGuideBottom and secure it in place with the M2x20 screw passing through the ArrowGuideBottom. (See fig. 2 below)

Next insert two of the M3x16 screws through the outer front holes of ArrowGuideTop and screw them in deep enough to attach the StringPulley_inner cylinders around the screws.

Next, loop two strong rubber bands through the two holes on the ArrowSled and then loop them around the StringPulley_Inner cylinders and screws. You can then line up the M3x16 screws on ArrowGuideTop with the front outer holes in ArrowGuideBottom, making sure to place the ArrowSled's rectangular block inside the channel in ArrowGuideBottom. (See fig. 3). Once the sled is in between ArrowGuideTop and ArrowGuideBottom, you can screw the M3x16 screws to secure the Top and Bottom guides together.

You should be able to pull back the ArrowSled and have it lock with the StringReleaseHook. If all seems to be working, repeat this again for the other two copies of the sub-assembly.

If you havent done so already, gather your PVC pipe (about 1in OD, 3/4in ID) and cut it to 130mm. Next, youll need to print the following parts:

RevolverGuideFrame x 2

PipeSpacer

FrameStopper

ArrowGuide Sub-Assembly x 3 (including the unused screws)

Once your pipe is cut to the correct length, youll want to cut some small slots on either end. You can use a hand saw or preferrably a dremel rotary cutter to cut diametric 3mm x 3mm slots into the ends of the pipe. These "index slots" are there to line up with the small tabs on the PipeFrontCap and Handle so they dont twist. Do this now before the following steps. (See fig. 4)

Take one of the RevolverGuideFrames and prepare to attach it to the ArrowGuide Sub-assemblies via their rear screw holes

Line up the ArrowGuides rear screw holes with the RevolverGuideFrame's screw holes such that the ArrowGuideBottom is flush with the flat portions of the GuideFrame. Screw the M3x20 screws through the ArrowGuideTop and ArrowGuideBottom's rear holes and all the way through until they are fully mated into the GuideFrame. Do the same for the other two ArrowGuide sub assemblies.

Next youll do the same for the other RevolverGuideFrame and the front screw holes in the ArrowGuide sub assemblies. There are two holes in ArrowGuideTop to allow access for inserting the M3x8 screws through ArrowGuideBottom and into the GuideFrames. Do this for all three sub assemblies such that they are all secured in a radial pattern (See fig. 5)

Now insert the rear GuideFrame ring around the PVC pipe a few inches, then insert the FrameStopper ring afterwards. Insert the PipeSpacer after that and then finally insert the front GuideFrame ring. The GuideFrame rings and ArrowGuide subassemblies should be able to rotate smoothly around the pipe while the PipeSpacer and FrameStopper should have more friction as they should not move relative to the GuideFrames. (See fig. 6)

Finally, Insert the cylinder of the Handle into the rear end of the PVC pipe and slide the rear GuideFrame up against it so that the slots cut into the pipe line up with the small tabs in the Handle.

To complete the assembly, youll need to have everything from the previous steps, plus the TorsionSpring and PipeFrontCap along with an M3x8 screw

At this point, the handle should be inserted into the rear end of the pipe, the 3 ArrowGuide sub-assemblies should be attached to the RevolverGuideFrames and mounted to the pipe, and the PipeSpacer and FrameStopper should be on the pipe between the two RevolverGuideFrames.

Take the PipeFrontCap and insert it into the front end of the PVC pipe and align it such that the two tabs are inserted into the slots cut into the pipe.

Take the TorsionSpring and insert the center cylinder into the keyhole in the PipeFrontCap such that it is tightly mated. Secure it with the M3x8 screw.

Next, insert the tab on the outer end of the TorsionSpring spiral into one of the 3 smalll slots in the front RevolverGuideFrame. It should fit tightly, but if not, use some glue to secure it in place. (See fig. 7). You should now be able to rotate the ArrowGuide and GuideFrame around the pipe clockwise (with the muzzle facing away from you) and have the torsion spring apply torque to attempt to rotate it back counter clockwise.

With the PipeEndCap and TorsionSpring in place, slide the FrameStopper as far backwards as you can until the Rear RevolverGuideFrame is flush with the rear end of the pipe. Glue it in place with a small dab of glue. It shouldnt be too tight but it should sandwich the rear RevolverGuideFrame between itself and the lip of the Handle. Ensure that the small triangular tab on the FrameStopper aligns with the left side edge of the 5mm slot in the ArrowGuide and the MainTrigger. Once its aligned, hold in place while the glue dries. It helps to align one of the ArrowGuide's rear slot with the trigger (the trigger should fit exactly into the slot) while positioning the StringReleaseHook's bottom tab such that its touching the left face of the FrameStopper tab. If they all line up, youre in good shape!

The main assembly is now complete, congrats! Now go ahead and print 3 arrows so you can test your shiny new Revolver Crossbow

To load the crossbow, youll want to twist the rotating frame around the pipe until there is enough tension on the spring for it to want to spin Counter Clockwise when released. Once this tension has been achieved, hold the frame in place and pull back the arrow sled on the Arrow Guide closest to the FrameStopper's tab. Pull the sled all the way back and then close the StringReleaseHook onto the Sled such that it is held in place. Rotate the Frame Clockwise past the FrameStopper tab and repeat this process for the other two Sleds until the last StringReleaseHook's lower tab holds the entire frame in place against the tension of the TorsionSpring. (See the last video for more info).

Lastly, insert an arrow in between each of the ArrowGuides until the rear end of the arrow is inserted into the small chamber of the ArrowSled and is loosley held in place. Do this for each of the 3 Arrows. There should be just enough friction to hold the arrows in place even when the arrow tips are pointed down towards the ground.

You can now fire the weapon! Pulling the trigger all the way back should cause the top end of the trigger to push against the rear of the StringReleaseHook, causing it to rotate and release the ArrowSled, sending the arrow shooting forward!

While the trigger is held down, the rotating frame should be locked in place. Releasing the trigger should unlock the frame and allow it to rotate counter clockwise until the next StringReleaseHook's bottom tab hits the FrameStopper's triangular tab, making it ready for the next shot. Repeat the firing process until all arrows have been fired, and bask in the glory of your Semi Auto Revolver Crossbow, along with the many painstaking hours I spent engineering this thing :)

I hope you enjoy this design and expand upon it as I always welcome improvements

Print Settings

Printer brand:

Prusa

Printer:

I3 MK3S

Rafts:

No

Supports:

No

Resolution:

0.2mm and 0.3mm

Infill:

20%

Filament_brand:

prusament

Filament_color:

white

Filament_material:

PLA

Notes:

Here are the support / layer height settings for each part. If infill isnt listed, just use 20%.

ArrowGuideBottom (No Supports, 0.3mm)

ArrowGuideTop (No Supports, 0.3mm)

RevolverGuideFrame (No Supports, 0.3mm)

ArrowSled (Supports on build plate only, 0.2mm)

StringReleaseHook (No Supports, 0.2mm)

StringPulley_Inner (No Supports, 0.3mm or 0.2mm)

MiniArrow (No Supports, 0.2mm, 100% infill)

TorsionSpring (Supports on build plate only, 0.2mm, 100% infill)

PipeFrontCap (No Supports, 0.3mm)

MainTrigger (No Supports, 0.2mm, 100% infill)

FrameStopper (No Supports, 0.3mm or 0.2mm)

PipeSpacer(No Supports, 0.3mm or 0.2mm)

Handle halves (Supports on build plate only, 0.3mm)

Post-Printing